Our references in tank building

- New construction of a double bottom and the fixed roof

- Dismantling of the existing fixed roof by means of crane lifting and subsequent scrapping

- Dismantling of the raised floor

- Assembly of a new double bottom incl. connection to the leakage monitoring system

- Assembly of a new tank roof, the tank roof was prefabricated on an adjacent area and placed and assembled as a whole on the tank

- Installation of new tank bottom and new heating coil

- Hot water-powered heating coil with a length of 3,719 m

- Engineering for the new tank bottom and the new heating coil

- Insertion of an assembly opening into the tank (doorsheet, 4 x 4 m) using a high-pressure water jet

- Manufacture, delivery, and installation of the new tank bottom (membrane) and new bottom edge plates

- Manufacture of the new edge segment

- Delivery and installation of new tank bottom sump and residual emptying line

- Cutting of nozzle fields in the tank shell for the heating coil and the filling and emptying pipe

- Static calculation for the subframes before cutting out nozzle fields from the tank shell

- Installation of subframes before insertion of nozzle fields using water jet cutting

- Delivery and installation of new nozzle field for the heating pipe (prefabricated connection field with 8 connections for the heating pipe entering the tank and 8 connections for the heating pipe exiting the tank)

- Delivery and installation of sampling connections, temperature connections, pressure connections, and Protego connections

- Installation of brackets/supports and the complete heating coil with a length of 3,719 m

- Welding of the heating coil, total number of welds > 500

- Final sealing of the door sheet in the tank jacket

- NDT of all newly installed components

- Handover of the tank to the operator for final water filling

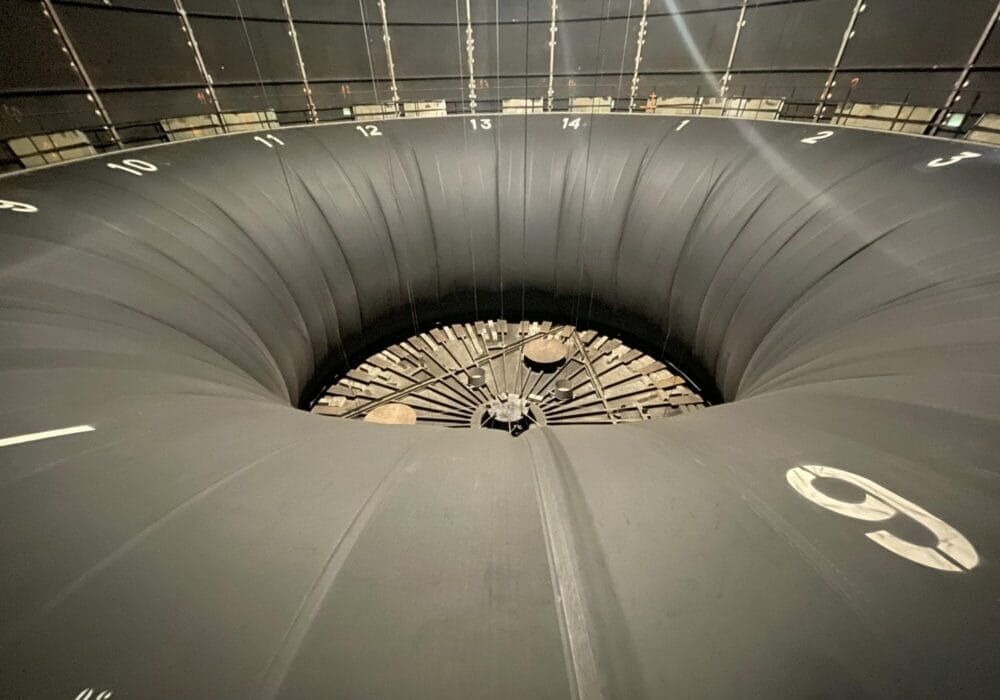

SOYK Industrial Services GmbH was commissioned to repair a dry gas tank (membrane gas tank) as part of this project. The tank has a diameter of 25 m, a shell height of 23 m, and a tank capacity of 9,400 m³. In this case, the membrane is attached to a floating horizontal disc. During operation, the membrane is stretched into an arc shape by the gas pressure between the attachment to the disc (piston) and the tank housing. Before carrying out the repair work, SOYK GmbH recorded the actual condition of the membrane gas tank.

The residues left in the tank after various rinsing processes (sludge) are sucked out by the cleaning robot from SOYK GmbH using our associated suction truck and our ATEX screw pump (rough cleaning).

Specifically, the following work steps were carried out by SOYK GmbH as the general contractor:

- First, the membrane was patched in several places so that a test run could be carried out. The test run was performed with air using mobile blowers that were installed outside the gasometer for this purpose.

- It was determined that the installed diaphragm was too long, the diaphragm disc was twisted or not positioned correctly in the tank, and therefore the diaphragm cable guide also had to be realigned.

- This was followed by a complete survey of the gasometer with the aim of determining its actual condition as accurately as possible in order to derive the appropriate measures to ensure the smooth operation of the gasometer in the future. In addition, the required dimensions of the new membrane were determined on the basis of the current survey results.

- In a further step, based on the preliminary investigations, the disc of the dry gas container was floated using the mobile blowers and realigned or repositioned centrally in the container in accordance with the measurements taken previously.

- The old membrane was then dismantled, starting with the fastening to the disc and then to the tank jacket or to a circulation pipe in this container. The fastening rails and the membrane were then disposed of properly.

- Based on a structural analysis commissioned by us to assess the stability of the dry gas tank, longitudinal stiffeners were attached to the tank shell due to axial buckling. For this purpose, an internal scaffold was installed along the tank wall, from which the grinding and welding work on the tank shell was carried out.

- The rope guides of the dry gas tank were replaced and their positions above and below the disc and on the tank jacket were moved, as the disc of the gasometer had also been realigned and repositioned centrally in the tank. The required new positions of the deflection rollers/rope guides were precisely measured in advance. Based on the measurement results, these were dismantled and then welded back into their new positions to ensure smooth operation of the gasometer in the future.

- In the next step, an installation opening was cut into the tank jacket, through which the 11-ton transport box containing the new membrane was inserted via a rail system, unfolded, and then reinstalled.

- The gasometer piston was previously covered with a scaffolding platform to create a flat surface that would allow the membrane to unfold safely. Due to the heavy weight of the ramp and scaffolding platform mentioned above, additional wooden supports were installed below the piston to secure it.

- Once these complex preparations had been completed, the nitrile membrane was unfolded in the tank and pulled upwards using cable pulls—which were mounted on a total of 14 roof connections on the tank roof—before being screwed tightly into place on the upper mounting ring. The membrane was then mounted on the gasometer piston.

- Finally, the membrane was completely assembled and then subjected to a leak test in the course of various test runs using air in the presence of a testing organization. Result: The tightness of the membrane was verified and documented to the operator.

- Then the moment finally arrived: after almost a year of extensive repairs, the official test run of the gasometer was successfully completed on February 20, 2025, in the presence of the operator.

- We are proud to have completed this complex project well ahead of schedule and would like to thank all our partner companies for their support and the operator for their trust in our work.

- Dismantling / removal of the old tank roof

- Examination of all static documents and execution drawings for the new construction

- Engineering, documentation incl. NDT inspections

- Creation of a detailed work schedule

- Creation of a work-related risk assessment

- Preparation of a train study

- Delivery and provision of the necessary construction site equipment

- Separation of the roof below the roof edge using the flame-cutting method

- Arrival/departure, assembly/dismantling of a 400t mobile crane, incl. lifting gear (round slings, sling chains)

- Completely lift the roof using a mobile crane and place it on the ground directly next to the tank

- Cut up the old tank roof and load the scrap into containers

- Disposal of the scrap

- Lifting the new tank roof

Services in detail for the new construction of the tank roof:

- Cutting of roofing sheets 5mm

- Stamping of batch numbers

- Rolling of sheets

- Cutting of U-profiles U120 / 140 and angles 80/8

- Cutting of additional gusset plates and platform supports

- Stamping of batch numbers

- Rolling of profiles

- Welding additional gusset plates into roof girders according to structural analysis specifications

- Welding additional gusset plates into U140 corner brackets in accordance with structural analysis specifications

- Production of support brackets for railings

- Prefabrication of the walking platform, width 500 mm

- Prefabrication of all-round railing

- Additional supports for the platform construction on the tank roof in accordance with structural analysis specifications

- Production of gratings for walking platform, width 500 mm

- Supervision of cutting and prefabrication in the course of the WPK

- Prefabrication of roof supports DN 25 - DN 600

- Welding the nozzles into the tank roof

- Dimensional checks of all manufactured components

- Packing and loading onto trucks for delivery to the construction site

- Prefabrication of auxiliary structures for roof dismantling/assembly

- Prefabrication of lifting eyes for the tank roof

- Prefabrication of 10 pipe holders to hold the pipes

- New brackets for connecting bridge to neighboring tank

A new top layer was to be applied to the existing tank and various components (suction and measuring lines, manholes) were to be replaced. The following measures were carried out in detail:

- Insertion of installation openings in the outer and inner tank shell using high-pressure water jet technology

- Construction of a gravel ramp including Stelcon plates as a platform for the subsequent installation of the new tank floor plates

- Crane provision

- Scaffolding erection

- Dismantling of old manholes and pipelines using high-pressure water jet technology or plasma cutters

Installation of a new topsoil in the tank, our services included in detail:

- Planning, work preparation and work planning

- Prefabrication of the topsoil and the associated corner brackets

- Prefabrication of various brackets and new discs for the topsoil

- Prefabrication of 4 test, suction and measuring lines

- Prefabrication of 2 pipes in the tank farm

- Prefabrication of 3 DN 800 manholes

- Delivery and installation of manholes, pipelines and topsoil with corner brackets

- Transportation of all prefabricated components

- Final sealing of all assembly openings

- Welding supervision during prefabrication and assembly

- NDT, documentation and as-build

In a current project - in which a water-polluting substance penetrated the subsoil - the aim was to obtain a spatial idea of the geological structure of the subsoil.

Several geological sections were created for this purpose. To create the sections, the results of previously drilled boreholes (percussion coring) were compiled, evaluated and combined to create an overall geological picture. To illustrate the geological properties of the subsoil, the layers were summarized on the basis of the most important petrographic properties determined during the drilling work.

The result is a hydrostratigraphic section that reflects the location, thickness and extent of well permeable layers to groundwater aquifers in the subsurface.

With the help of this representation, an estimation of the lateral and vertical spread in the subsurface can be made in the event of damage, such as the entry of water-polluting substances into the subsurface (oil spills), taking into account analytical findings.

Profile section A-A

Profile section B-B

You want more references or examples of our work? No problem, just contact us.

Get in touch